Projektbeispiel

Modular design for linear axes

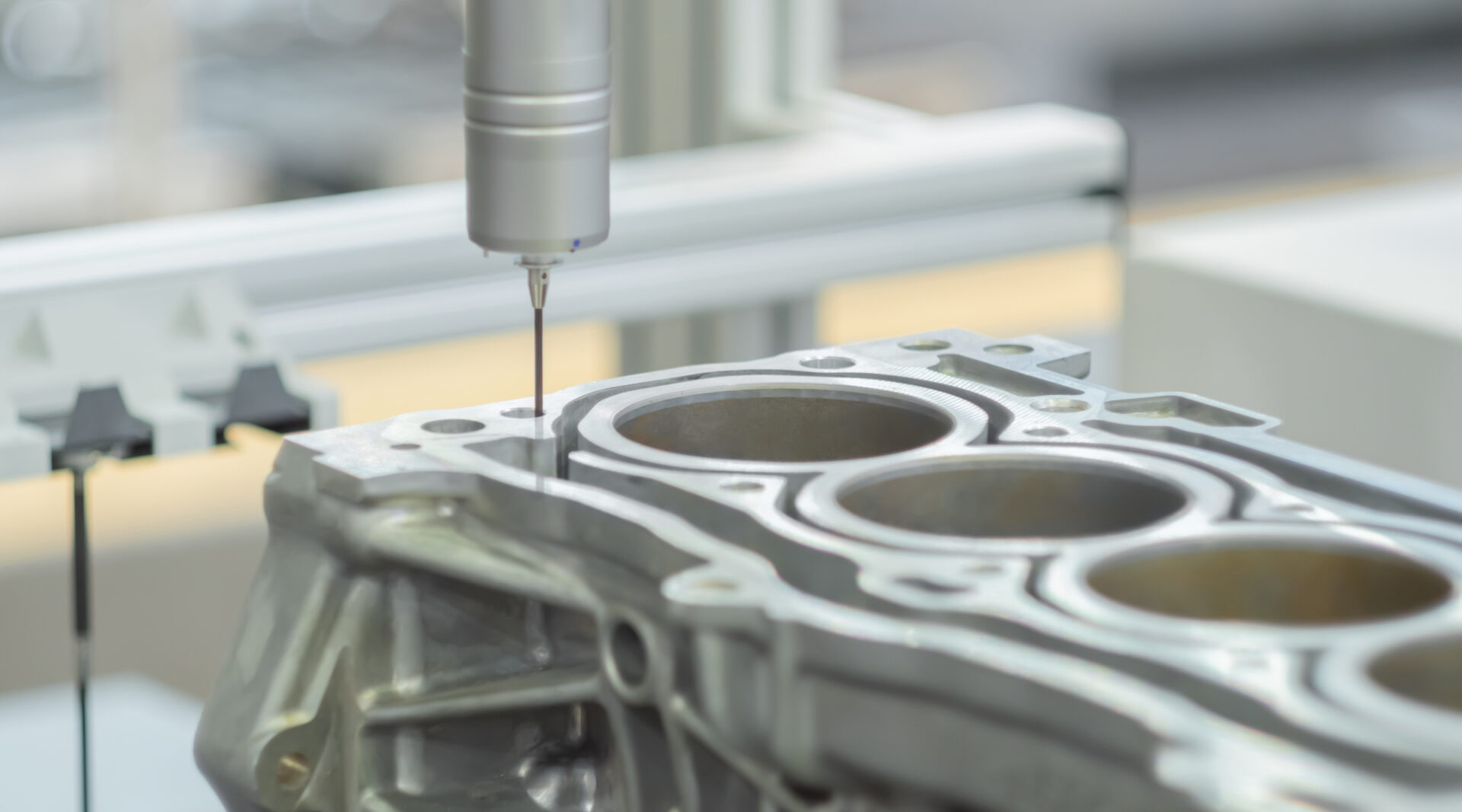

For devices for tactile surface and roughness measurement, cost savings of approx. 20% and thus competitive advantages were to be achieved by means of a standardisation of the linear axes. The task was to develop a system consisting of standardised subsystems, through the combination of which all requirements for measurement tasks from the relevant market areas or segments can be covered. To encourage rethinking and the search for new solutions, the existing products were deliberately ignored at the beginning of the project. Instead, the relevant market segments with the required axis capabilities to fulfil a specific measurement function were defined. By stating which requirement is placed on a particular axle capability and how often, it was possible to determine an initial tendency of the modular system. With the result out of five workshops, the client finally had the basic definition of the future modular system in the form of the requirements to be fulfilled from the market point of view, which still had to be transferred into a “requirement specification” with concrete technical solution concepts.